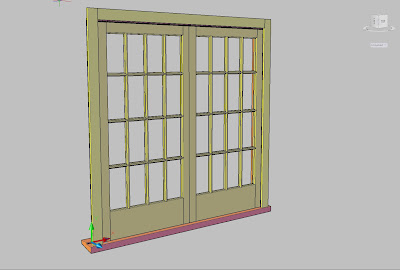

The picture shows a pair of double doors. Just opening a set of these, it would never occur to you that there are two different styles (the uprights on the left and right), and what a pain they have caused. They must overlap in the middle, and this has been a bit of a trial.

The picture shows a pair of double doors. Just opening a set of these, it would never occur to you that there are two different styles (the uprights on the left and right), and what a pain they have caused. They must overlap in the middle, and this has been a bit of a trial.Anyway, this window stuff is now finished, and unless my friend R wants a set of horizontally sliding doors, or windows that slide up and down, this is now a project done.

That is, unless I get excited about doing a costing part.

The next project is to do a bit on Java. How this can be connected to Autocad I'm not sure and what the next project should be I'm not sure. Maybe it is just the time of year.

I had a flash of the blinding obvious regarding drawing of houses. It seems that almost every part of a house model is controlled by the floor plan. If you could have a program that generates a set of foundation plans automatically from a floor plan?

Same with the roof. Which just leaves the walls and windows. The exterior walls would be controlled by the floor perimeter, so they are covered. The exterior walls are then able to be enumerated and so windows as a separate item could be assigned to a particular wall.

That leaves just the interior walls. Maybe these are controlled by the "room usage"?

Which comes back to Java: I know this is an object oriented language and I have done a bit of research on it and it seems very good.

It now occurs to me that someone else has thought of all of the above, and is possibly feverishly putting the finishing touches on a program which, unfortunately, will put a lot of architects out of work.